F1 COMPRESSION INSTALLATION GUIDE

STEP 1

To cut the pipe ensure the blade of the cutter is straight across the pipe. This will ensure a firm connection to the fitting.

STEP 2

Prepare the ends with the reamer. Push into the pipe and while exerting pressure, twist the bevel all the way round. Plastic shavings should come away from the pipe. The bevel is complete when no more appear.

STEP 3

Slide the nut over the pipe followed by the olive as indicated.

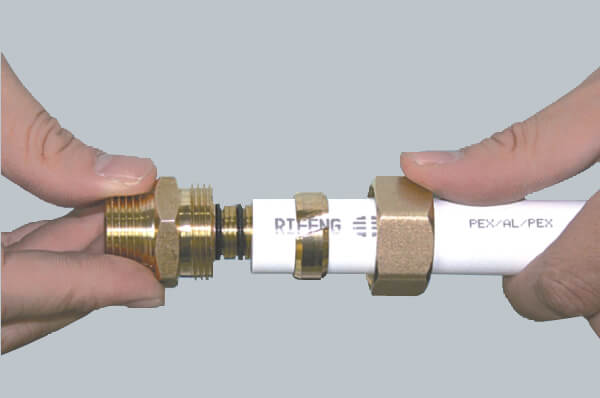

STEP 4

Insert fitting. Check O-rings are intact and free of dirt. Insert the main body of the fitting into the pipe. if stiff then the pipe is not fully bevelled.

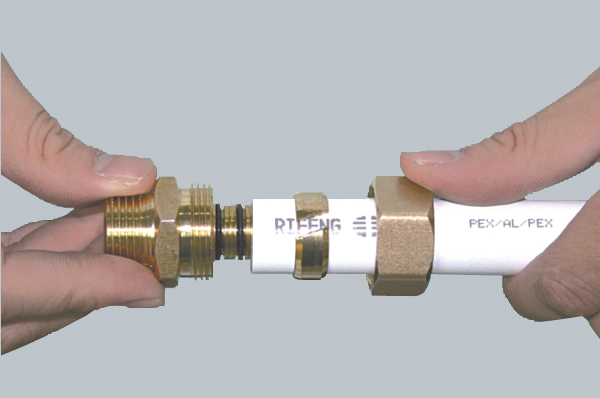

STEP 5

Tighten with suitable wrenches. Slide the nut, olive and fitting together and tighten with spanners. This completes the compression fitting.

Types of Compression Fittings and Compression Valve Fittings

When working with plumbing or underfloor heating systems, it’s useful to understand the types of compression fittings available and where a compression valve fitting comes into play. Knowing the right option makes fitting compression joints quicker, safer, and longer-lasting.

Common Types of Compression Fittings

-

Straight Compression Connectors

-

Join two pipes of the same size in a straight line.

-

Often used for extending or repairing pipe runs.

-

-

Equal and Unequal Tees & Elbows

-

Equal tee: All outlets are the same size, used when pipework continues at a uniform diameter.

-

Unequal tee: Feature a branch of a different diameter to connect pipes of varying sizes.

-

Plumbing Elbows (90° or 45°): Allow changes in direction without compromising the joint.

-

-

Wall-Plated and Radiator Elbows

-

Provide a neat finish when connecting to radiators or pipework entering through walls.

-

-

-

Combine a valve with a compression joint, such as isolation or stop valves.

-

These are especially handy where water flow needs to be controlled or shut off without soldering.

-

Why Choosing the Right Fitting Matters

Each type of compression fitting is designed for a particular function - whether that’s joining two pipes, creating a branch, turning a corner, or adding a valve. Selecting the correct option makes fitting a compression fitting easier, ensures a secure seal, and reduces the risk of leaks.